Overview

Industrial plants or plants in public infrastructure areas are often spread across wide areas, sometimes even across national borders. The range of telecontrol products offers complete solutions with the following features:

- Connection of distributed process stations/remote terminal units (RTUs) to one or more control centers

- Use of different public or private communication networks for monitoring and controlling the telecontrol substations

- Event-driven or cyclic exchange of the process data including time stamp via special telecontrol protocols

- Operating personnel have efficient control of the overall process

- Online access to the substations for diagnostics, remote programming and maintenance

TeleControl Basic

TeleControl Basic is a simple remote control and remote maintenance system optimized for the use of public communication networks such as mobile wireless and internet for connection to the substations.

It comprises the TeleControl Server Basic control center software and substations of the type SIMATIC S7-1200, ET 200SP and RTU3000C. In addition to communication between the control center and the substations, the system also enables internode communication between substations.

Small-scale applications with few outstations can be implemented, as well as large-scale plants comprising up to 5000 outstations.

TeleControl with IEC 60870, DNP3 and SINAUT ST7

TeleControl Professional includes telecontrol systems for extensive, expanded applications of the process industry. From SIMATIC PCS 7, SIMATIC WinCC or non-Siemens control systems using OPC, outstations based on SIMATIC S7-1500, ET 200SP, S7-1200, S7-300/400 and RTU3000C can be monitored and controlled. The outstations and substations can communicate with each other as well as with one or more control centers. TeleControl Professional has a modular design throughout and can be used with extreme flexibility.

Both telecontrol systems can be connected to a non-Siemens control center system (OPC client) via OPC.

Benefits

- Secure and economic remote monitoring and control of process stations

- Global remote access to widely distributed machines and plants

- Quick and easy commissioning due to perfectly matched system components

Telecontrol Professional

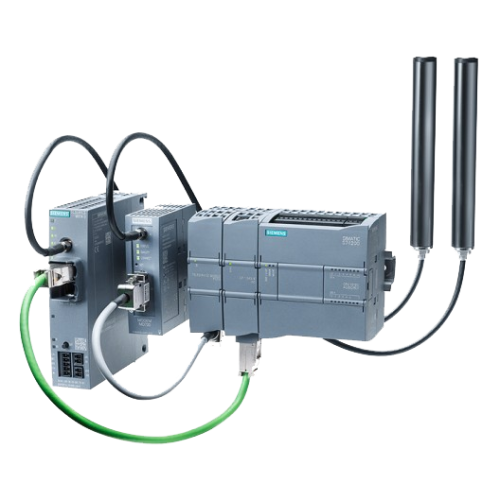

Sample configuration: TeleControl Professional

TeleControl Professional is a telecontrol system based on SIMATIC S7 for the fully automatic monitoring and control of remote control stations which exchange data with one or more control centers, or with each other, via a wide range of WAN media.

TeleControl Professional facilitates an integrated communications concept (TIA) and complete integration into the SIMATIC environment. The modular design and the support of a huge variety of network forms and operating modes including IP-based networks permit the design of flexible network structures that can also contain redundant links.

By using all forms of transmission media (e.g. dedicated line, wireless, dial-up networks, mobile wireless, DSL), the networks can be optimally adapted to the respective local conditions.

The system also supports data exchange with devices of the previous system SINAUT ST1 (based on SIMATIC S5).

Benefits

- All conventional and IP-based WAN media can be combined as required, including path redundancy

- Event-driven data transmission incl. time-stamping

- Local data storage

- Remote programming and remote diagnostics

- Integrated operator control and monitoring concept for WinCC/PCS7 or connection to non-Siemens systems via OPC

Application

The TeleControl Professional system has proven itself in the smallest plants with only a few process stations, but also in complex networks with many hundreds of stations.

Examples of the range of uses:

- Safe supply of drinking water, gas or district heating for private and industrial consumers via branched networks

- Economical transportation of gas, oil or oil products through pipelines

- Reliable recording and transmission of process data from environmental monitoring systems

- Remote monitoring of wastewater systems

- Control of beacons, unit-type district heating power stations, conveyor systems or transportation systems

Design

The TeleControl Professional system is based on the SIMATIC systems S7-1500, ET 200SP, S7-1200, S7-300, S7-400, the RTU3000C family and on WinCC/PCS 7. It supplements these systems with the special communications processors for S7-1200 and SINAUT components listed below, comprising hardware as well as software.

Hardware Components

- Communications processors (CPs) for S7-1200 and ET 200SP

- TIM communications modules

- Mobile wireless components (GSM/GPRS/UMTS)

- Industrial modems and routers (SCALANCE M)

- Connecting cables

Software Components

SINAUT Engineering Software

- SINAUT TD7 library; contains blocks for the SIMATIC S7 CPU

- SINAUT configuring and diagnostics software for the programming device

Software for the Central Control Center

- SINAUT ST7cc; the SINAUT add-on for WinCC

- WinCC TeleControl; add-on for SIMATIC WinCC for telecontrol applications

- PCS 7 TeleControl; add-on for SIMATIC PCS 7 for telecontrol applications

- SINAUT ST7sc; software for interfacing ST7 with control centers that can operate as OPC clients

Function

Software Components

The telecontrol components support the set-up of complete hierarchical communication networks comprising terminals, node stations and control center.

For the exchange of information between the individual devices, conventional WANs can be used, such as dedicated-line, wireless and dialup networks as well as IP-based WANs such as DSL, GPRS, UMTS, LTE, Internet, etc.

There are no restrictions on the combination of WAN types in a project. Point-to-point, line and node network topologies can be set up. Hybrid configurations of these basic structures are also possible.

A station can be linked using two transmission paths to permit redundant data transmission. The two paths can be of the same type or different, e.g. dedicated line plus GPRS, or ISDN plus wireless.

The following network topologies are possible in the WAN:

- “Point-to-point”

- “Line”

- “Star”

- “Tree”

- “Ring”

The graphics below show examples of different network topologies that can be implemented with the components listed above.

SINAUT ST7cc/sc control station with redundant WAN connection

Different communication media in a SINAUT ST7 system

The Control Center

A number of different variants can be selected as components of the central control center:

SINAUT ST7cc

This is the ideal control center system for both SINAUT ST7 and SINAUT ST1. It has been designed specifically for event-driven and time-stamped data transmission on the SINAUT system and can be set up as a non-redundant or redundant system (to supplement the WinCC/PCS 7 redundancy package).

PCS 7 with PCS 7 TeleControl

This is the ideal control center system for plants in which larger local automation tasks have to be connected to telecontrol interfaces. In addition to SINAUT ST7, remote stations with other communication protocols can be connected, e.g. over DNP3 or IEC -60870-5-101/-104. 1)

WinCC TeleControl

Control center system for plants with the WinCC HMI software, expanded with telecontrol connections. WinCC TeleControl provides the connection of SIMATIC substations that communicate via IEC 60870, DNP3 or SINAUT ST7.

SINAUT ST7sc

OPC server for interfacing control centers from other vendors via the OPC Client function

The SINAUT telecontrol technology can also be connected to control center systems from other vendors via the “Data Access Interface”. ST7sc features extensive buffer mechanisms which prevent data from being lost even if the OPC client fails. It can be connected to non-redundant or redundant clients.

Like the substations, the control center comprises a SIMATIC S7-300, an S7-400 or an S7-1500 controller.

This solution is suitable for simpler control centers in which only an up-to-date process image of the process data available in the stations is required. The station process control can be influenced by entering commands, setpoints or parameters. This S7-300, S7-400 or S7-1500 control center can also be used to extend a PC control center (SINAUT ST7cc or ST7sc), e.g. for data output on a panel and/or as an emergency operating system.

SINAUT ST7cc control center system with connected substations (RTU)

Classic WANs

The following conventional WANs can be used for data transmission:

- Copper dedicated lines, private or leased

- Private wireless networks (optionally with time slot procedure)/TETRA

- Dial-up networks (analog/ISDN/GSM)

IP-based WANs

Telecontrol communication is also possible via IP-based networks:

- Wirelessly, by using special wireless systems optimized for Ethernet, e.g. the components of the SCALANCE W IWLAN system

- Via fiber-optic conductors, e.g. through use of SCALANCE X switches with optical ports; distances of up to 120 km can then be covered

- Via public networks and the Internet using DSL or GPRS/UMTS/LTE

- Copper dedicated lines, private or leased

Change-driven data transmission

In the stations, the SINAUT software ensures that process data is transmitted between CPU and control center, e.g. ST7cc, and from CPU to CPU in the event of changes. Connection, CPU or control center failures are displayed. A data update for all participating communication partners is performed automatically following debugging or startup of a CPU or of the control center.

Permanently correct time

To enable subsequent and correct archiving of process data in the control system, all data frames are already assigned a time tag at their place of origin. The entire network is synchronized automatically – including daylight saving time changeover.

Local data storage

A special property of the TIM communications module used in the SINAUT ST7 system is the capability for saving data which must not be lost in the event of a connection fault or if the partner fails. A memory capacity is provided for up to 56,000 message frames.

The memory capacity helps to save money on dial-up networks. Various priorities can be assigned to the data to be transmitted. At high priority, a dial-up connection is established immediately. At low priority, data is initially saved in the TIM. This data is transmitted on the next connection that is made with the partner for any reason, for example if an item of information with a high priority is to be transmitted, or if the partner sets up a connection in order to exchange data.

It is precisely because the TIM module can save data and transmit it at a later point in time with a time stamp that the use of a suitable control center system must be ensured. It must also be possible to continue to process this data, specifically as regards subsequent archiving, if the data is received in the control center delayed by a number of hours or even days. Also archive compressions such as the creation of mean, hourly and daily values cannot be performed until all data for the relevant period has been received. The standard SINAUT control center on the basis of WinCC, when supplemented with the SINAUT software ST7cc, is ideal for this task.

SINAUT remote programming and remote diagnostics

In industries in which SINAUT is used, the terminals are distributed across wide areas and are often situated in locations that are difficult to access. Faults which require a visit to be made to a terminal of this type are associated with long journeys. SINAUT ST7 can provide the ideal solution for such circumstances: Remote programming and diagnostics via the telecontrol network. All diagnostics and programming functions provided by SIMATIC and SINAUT for station automation and WAN communication can be used via the telecontrol path – without interrupting process data transmission.

Alarms as text messages

In order to alert standby service personnel, event-driven text messages can be sent to mobile phones from the CPUs. An acknowledgment that a message of this type has been received can be sent back to the sender CPU from the mobile phone. A text message can also be output as email, fax or voice mail if the mobile service provider offers these options.

1) For further information, see Catalog ST PCS 7.1

Integration

Protocols

IEC Protocol 60870

IEC 60870-5-101, -104 are standardized, vendor-independent telecontrol protocols. They enable remote communication via both conventional and IP-based WANs. The following modules are offered for implementation of an RTU with IEC 60870-5 based on the SIMATIC: CP 1243-1, CP 1243-8 IRC, CP 1542SP-1 IRC, TIM 1531 IRC plus the compact RTU3000C module.

Possible operating mode in the IP-based WAN:

- Spontaneous mode

DNP3 Protocol

The DNP3 protocol (distributed network protocol) is a standardized, manufacturer-independent telecontrol protocol. It enables remote communication via both conventional and IP-based WANs.

Possible operating mode in the IP-based WAN:

- Spontaneous mode

Possible operating modes in the conventional WAN:

- Polling

- Polling with time-slot procedure

- Spontaneous operation (for dialup networks)

SINAUT ST7 Protocol

SINAUT ST7 enables SINAUT communication via both conventional and IP-based WANs. In addition, the addressing options have been extended:

- Up to 10 000 stations can be addressed

(maximum of 254 for ST1) - Frames contain a source and a target address, (ST1 frames only contain either a source or a target address).

The ST7 protocol also supports “PG routing”, i.e. remote programming and remote diagnostics via the WAN without interrupting SINAUT data traffic. PG routing and data traffic share the available bandwidth on the transmission path; PG routing is simply allocated a higher priority.

Possible operating mode in the IP-based WAN:

- Spontaneous mode

Possible operating modes in the conventional WAN:

- Polling

- Polling with time-slot procedure

- Spontaneous operation (for dialup networks)

SINAUT ST1 Protocol

This protocol is used in the SINAUT ST1 system, which is based on the SIMATIC S5 system. However, the SINAUT ST7 system also supports this protocol. Existing SINAUT ST1 systems can thus be further expanded with the SINAUT ST7 system, or existing system components can be replaced with ST7 devices.

Possible operating modes:

- Polling

- Polling with time slot procedure

- Spontaneous operation (for dialup networks)

Please note that only modems/transmission devices suitable for 11-bit asynchronous characters may be used in both polling modes. However, the “spontaneous” mode supports transmission with both 11-bit and 10-bit asynchronous characters.

Operating Modes

In polling mode, data exchange is controlled from the controller. It calls the connected terminals (including node terminals) in sequence. Terminals with modified data send this data as soon as they are called. Terminals with no modified data at the present time simply acknowledge the call. Data from the CPU to the terminals can be transferred at any time between the individual calls.

The ST7 protocol supports direct data transmission between substations. During this type of communication, data is always exchanged via the polling control center TIM.

- Polling with time-slot procedure mode is used on a radio network on which the use of the radio frequency assigned by the registration authorities has to be shared with other operators. Typically, each operator has six seconds per minute to exchange data with its terminals. Once this time has elapsed, the frequency must be enabled for the next operator. During the allocated time slot, this type of polling operates in the same way as standard polling.

The ST7 protocol supports direct data transmission between substations. During this type of communication, data is always exchanged via the polling control center TIM.

In order to exactly observe the time slot, the polling control center TIM must be directly supplied with the DCF77 or GPS time. - Spontaneous mode for data exchange on dial-up networks:

Different priorities (normal, high or interrupt) can be assigned to the data of the station or node station for transmission in the dial-up network. Data to be sent by the control center always have the high priority. If data with a high or alarm priority is awaiting transmission, a dial-up connection is established immediately. At normal priority, data is initially saved in the terminals. This data is transmitted on the next connection that is made with the partner for any reason, for example if an item of information with a high or alarm priority is to be transmitted, or if the partner sets up a connection in order to exchange data.

The frames saved in the TIM are transmitted according to the FIFO principle, i.e. in the original chronological sequence, provided they are frames with high or normal priority. If alarm frames are present in the TIM buffer, these are always transmitted before the other frames.

Direct data transmission between substations is is possible with the ST7 protocol. - Spontaneous operation in the IP-based WAN

For transmission via an IP-based network, a permanent S7 connection is established in each case between two TIMs or between one TIM and the ST7cc/ST7sc. The two TIMs or the TIM and ST7cc/ST7sc exchange the data packages specific to SINAUT ST7 with application of the TCP/IP transport protocol. The transmission is performed with the resources of the S7 communication, in which the processing of the spontaneous data exchange depends on whether the transmitted volume of data is chargeable or not in the IP-based network.

Networks without volume tariff:

When data is transmitted, it is transferred immediately to the respective partner regardless of any priority.

Data is transferred in accordance with the FIFO principle. This does not apply to frames with “interrupt” priority. These are transferred before any other frames that are available in the buffer.Networks with volume tariff:

- In an IP-based network such as the GPRS network, the priority of the individual data frames (normal, high or interrupt) is taken into consideration, as in the case of a dialup network. Data with normal priority is collected and transmitted in larger blocks, as soon as a specific size of block is achieved or, at the latest, when the specified TCP/IP Keep-alive interval has expired. This saves transmission volume because a reduced frame overhead and fewer acknowledgment frames are required. Important data with high or interrupt priority is transmitted immediately. Normal frames that are buffered at this point are sent at the same time. Frames with normal or high priority are transmitted in accordance with the FIFO principle.

Possible operating modes:

- Polling

- Polling with time slot procedure

- Spontaneous operation (for dialup networks)

Please note that only modems/transmission devices suitable for 11-bit asynchronous characters may be used in both polling modes. However, the “spontaneous” mode supports transmission with both 11-bit and 10-bit asynchronous characters.

Network configurations and topologies

All networks and all transmission media can be combined in any way in a telecontrol project – both with each other in “node structures”, as well as in parallel in star topologies or in redundant configurations.

The graphics below show a selection of different topologies that can be implemented with the telecontrol components.

Basic Topologies

Differently structured telecontrol networks can be implemented in the wide area network (WAN) based on the following four basic topologies.

Media Versions

Depending on the support provided by the selected telecontrol protocol, various transmission media are available for these basic topologies, for example, dedicated line, private wireless networks, mobile wireless networks, dial-up networks (wireless/landline), DSL over Internet.

Some of these media versions are shown in the example of the star topology.

Combinations of basic topologies and media versions

Through a combination of several basic topologies of the same or different media versions, it is additionally possible to design more complex network topologies, even with redundant communication paths. This allows optimum adaptation to process requirements and to the existing infrastructure.

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.