A lot of energy can be saved in the drive train – far more than the use of energy-efficient motors and frequency converters stipulated by legislation. However, the maximum possible energy efficiency and cost-effectiveness can only be achieved by taking a holistic approach regarding the possible interactions and synergies of individual measures and combining them on an application-specific basis.

Seamlessly designed and optimised drive technology – extending from the line connection through the mechanical coupling to the driven load – is key to the development of energy-efficient and cost-effective operation of industrial plants and systems.

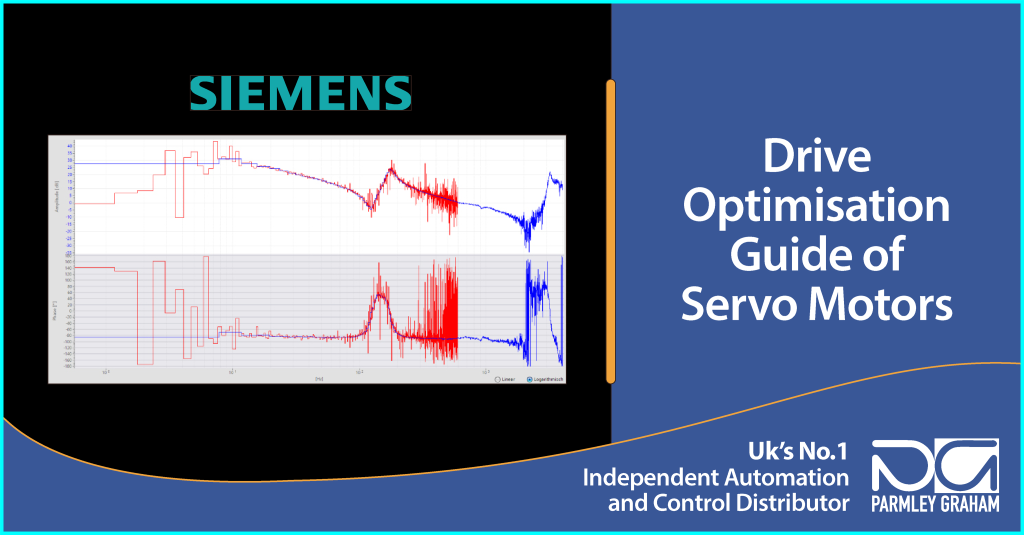

Drive Optimisation is an integral part of the commissioning of servo applications. Dynamic, stability and the limits of the mechanical system must be evaluated and optimised. Optimisation methods can often increase the productivity of the machine axis.

Our partner Siemens here provides a document that offers a basic guideline for servo drive optimisation with the drives SINAMICS S120, S210, and V90, as well as the motion controller SIMOTION D and SIMATIC S7-1500(T) using the commissioning software Startdrive.

Access the documentation, go to Siemens website

Find out more about Servo Drive Optimisation