Materials Handling

Efficiently helping streamline production process, reduce cost and improve productivity.

Effective materials handling in an industrial setting is essential for maintaining a smooth, cost-effective, and safe production environment. It helps the business meet production goals, reduce costs, and improve overall operational performance.

From simple motion control of a mechanical axis to AGVs and robotics. Our experts will work with you to understand your requirements and advise on solutions to meet your needs. We can help develop your knowledge and skills to engineer in-house or introduce our partners who can do this for you.

Whatever your requirements are, simply contact your local Parmley Graham branch today, or contact us to speak with our experts.

Find out more about our solutions or browse our Materials Handling products.

Overview

Simplified and cost-effective process, enabling optimised and successful operations.

E-commerce has changed the culture of how consumers purchase goods – expecting their items to be delivered quickly and inexpensively. Growing demand for customised and personalised orders requires more flexible systems, increasing pressure on the manufacturers, machine builders, and logistics to improve their material handling processes. At the same time, employee safety and environmental concerns are driving industry to prioritise cleaner / safer technologies by switching to robotic and automated systems.

Advanced technologies such as collaborative robots and electromechanical handling systems are becoming more affordable and easier to use enabling them to be used in a wider range of applications across almost all industries. Enhanced software allows you to plan and implement new systems efficiently as well as reduce engineering costs by up to 40% such as creating a digital twin to simulate detailed material handling processes.

Parmley Graham has a team of experts in the field to help with your material handling requirements. By partnering with the World’s best manufacturers we can offer a comprehensive range of solutions.

Material Transportation

This involves the movement of raw materials, components, and finished products from one location to another. Common equipment includes conveyors, forklifts, cranes, and automated guided vehicles (AGVs).

Storage and Warehousing

Effective storage solutions are essential for maintaining inventory and ensuring materials are readily available when needed. This can involve the use of shelving, racks, bins, and automated storage and retrieval systems (AS/RS).

Packaging and Protection

Proper packaging is crucial to safeguard products from damage, contamination, or deterioration. Packaging materials and methods may vary depending on the nature of the product.

Inventory Control

Efficient inventory management is essential to ensure that materials and products are available when required without excessive stockpiling or stockouts

Quality Control

Materials handling can include inspection and quality control processes to identify defects or issues in materials or products before they progress further in the production process

Automation and Robotics

Increasingly, automation and robotics are used for materials handling tasks, improving efficiency and reducing the need for manual labor.

Safety and Ergonomics

Safety measures are crucial to protect workers and equipment during materials handling. Ergonomic considerations are important for worker comfort and injury prevention.

Tracking and Traceability

Modern materials handling often includes systems to track the movement and status of materials and products, providing visibility into the supply chain.

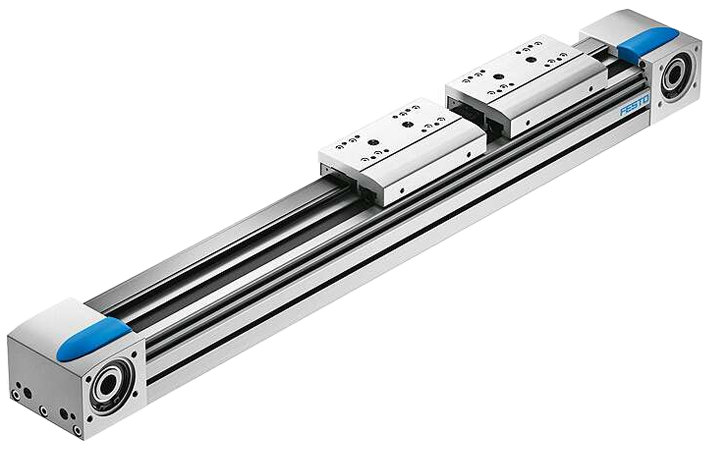

Products used in Materials Handling

Key Benefits

Delivering value through improved efficiency, safety and productivity.

Improved efficiency

Efficient materials handling ensures that raw materials, components, and products are in the right place at the right time, reducing delays and bottlenecks in production processes.

Better quality control

Materials handling processes can include quality checks and inspections to ensure that materials and products meet specifications, preventing defects from reaching the customer.

Reduced Downtime

Proper materials handling helps prevent disruptions in manufacturing by ensuring that materials are readily available when needed. This minimises downtime and keeps production on schedule.

Space Optimisation

Efficient materials handling can make the most of available storage space, reducing the need for excessive warehouse or factory floor space.

Reduced Cost

Streamlined materials handling processes reduce labor, storage, and transportation costs, ultimately contributing to lower operational expenses and higher profitability.

Reduced Material Damage

Careful handling and appropriate packaging methods can reduce the likelihood of materials or products being damaged during transport or storage.

Enhanced Productivity

Efficient materials handling allows factory workers to focus on value-added tasks rather than time-consuming material handling activities, leading to increased overall productivity.

Customer Satisfaction

Timely and accurate materials handling ensures that products are delivered to customers on schedule and in good condition, enhancing customer satisfaction and loyalty.

Inventory Control

Materials handling plays a crucial role in managing inventory levels, reducing the risk of overstocking or stockouts. This helps in maintaining a lean and cost-effective supply chain.

Reduced Environmental Impact

Optimised materials handling processes can lead to reduced waste, lower energy consumption, and a smaller carbon footprint, contributing to a more sustainable and environmentally responsible factory operation.

Safety

Industries

Food and Beverage

Materials handling in food and beverage manufacturing involves the movement, storage, and control of raw materials, ingredients, and finished products throughout the production process. Conveyor systems, automated storage and retrieval systems, and robotic handling equipment are used to streamline these processes.

Logistics

In logistics operations, materials handling is crucial for the efficient movement and management of goods. This includes the use of conveyor systems, forklifts, automated storage systems, and robotics. Efficient materials handling helps reduce transit times, minimise errors, and optimise warehouse space, ultimately improving the overall effectiveness of logistics operations from storage to distribution.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham are a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.