Elmleigh are system integration specialists for electrical and mechanical automation systems, specialising in Food and Drink and Parcel Distribution sectors.

Overview

A manufacturing client of Parmley Graham was experiencing persistent issues in its raw materials mixing process. The existing setup relied on level sensors that frequently provided inaccurate readings, resulting in inconsistent product quality and repeated mechanical failures across the production line.

Recognising that the end user lacked the in-house expertise to resolve these challenges, Parmley Graham brought in Elmleigh as a trusted solution provider.

Working closely together, Parmley Graham (PG) and Elmleigh identified the optimal technology for the task, the Siemens SIWAREX weighing solution, and developed a plan to fully integrate it. Elmleigh led the implementation, deploying a Siemens PLC and HMI to ensure seamless system communication and dependable long-term performance.

Challenge

The client’s primary concern was dosing accuracy – particularly with water. Inadequate water levels caused improper product consistency, which in turn led to mechanical strain, increased downtime, and reduced overall reliability of the production line.

Although the initial inquiry focused on hardware upgrades, it quickly became clear that a more integrated and precise solution was needed. Elmleigh was invited to become a strategic partner in solving the problem.

Solution

Elmleigh worked in close partnership with Parmley Graham to define the project’s scope and technical requirements. Through early consultation and detailed technical discussions, Parmley Graham took the lead in specifying components and guiding the integration process.

“Collaboration was key on this project,” said Luke Shinnie, Process Instrumentation Engineer at PG. “By combining our technical expertise with Elmleigh’s hands-on approach, we were able to overcome the initial challenges and deliver a reliable, high-precision solution.”

Sean Sharp, Automation Sales Engineer at PG, added. “This project is a great example of how strong collaboration and the right technology can transform collaboration and reliability. By combining PG’s product expertise with Elmleigh’s integration capability, we helped the client achieve precise, repeatable dosing and long-term process stability.”

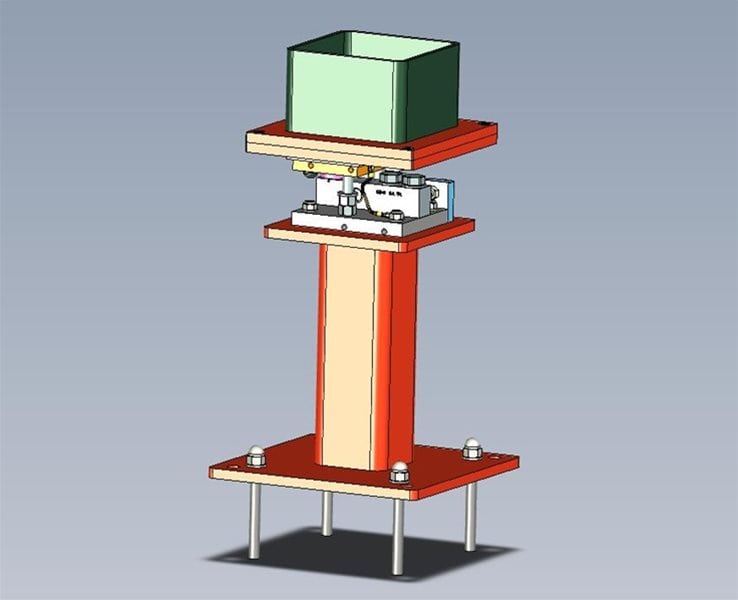

Elmleigh designed, manufactured, installed, and commissioned a new dosing system based on SIWAREX Load Cell technology, replacing the unreliable level sensors. The new system delivered accurate control signals directly into the client’s legacy control infrastructure – achieving seamless integration without major system overhauls.

Implementation

During installation, the team encountered compatibility issues between the load cells and the junction box, as well as discrepancies in weight readings. These were resolved through close collaboration with PG, ensuring the correct components were specified and validated.

“This project pushed us to explore new technologies and integrations,” said Richard Smith, Project Manager at Elmleigh. “The results exceeded expectations – not just in precision, but in operational efficiency and reliability.”

Results

The impact was immediate and measurable:

- Improved dosing accuracy led to consistent product quality.

- Reduced mechanical strain minimised breakdowns and downtime.

- Enhanced operational efficiency improved overall line reliability.

Impact

The project’s success has strengthened the partnership between Elmleigh and Parmley Graham, with ongoing technical support and collaboration. Building on this achievement, both teams are now exploring opportunities to apply the same SIWAREX technology in other applications — such as sugar measurement – extending the benefits to Elmleigh’s wider customer base.

Get in Touch

To discuss how the PG team can help, either email us at support@parmley-graham.co.uk or call 0191 478 0404.

Alternatively, click the button and complete your details: