Virtual Commissioning

Step into the future by merging the real and digital worlds with Siemens' Virtual Commissioning.

Prepare your operators before production begins, ensuring a fast, high-quality, and safe commissioning process. Harness a continuous data flow for smart decision-making and efficient production. Overcome traditional commissioning challenges, and create best-in-class products with ease. Embrace innovation and optimise your entire value chain from design to realisation.

Digitalisation for machine builders

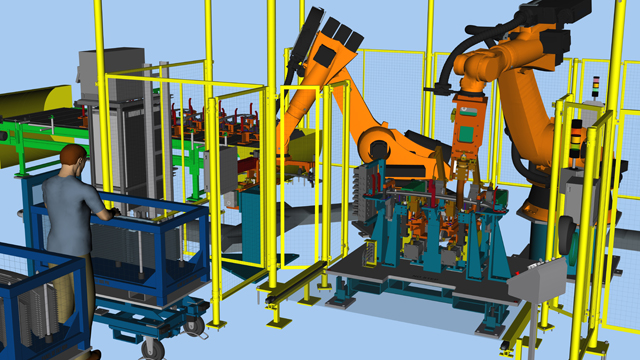

Siemens Digital Industries’ Virtual Commissioning uses advanced technologies to create and test digital concepts for complex machines in a virtual environment, reducing commissioning time and costs by mitigating risks.

Central to this is the Digital Twin, a CAD model created with software like NX Mechatronics Concept Design (MCD), allowing engineers to develop and test machine concepts virtually. The CAD model can be updated with design changes, ensuring ongoing improvement and optimisation.

Simcenter Amesim

An integrated, scalable system simulation platform for the virtual assessment and optimisation of mechatronic system performance.

Mechatronic Concept Design

Mechatronic Concept Designer (MCD) revolutionises the machine design process by enabling faster, higher-quality design through an integrated system engineering approach.

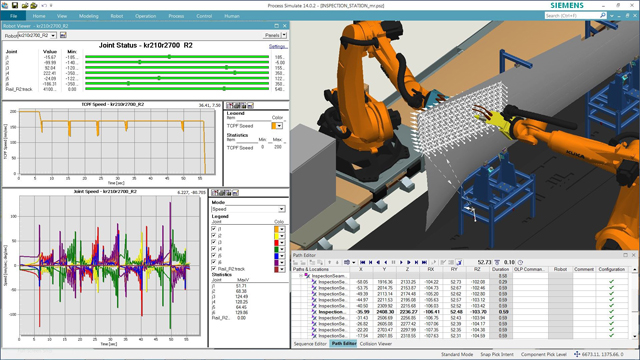

Process Simulate

Create virtual replicas of your production environment, enabling you to identify and address potential issues. Optimise resource utilisation, reduce errors, and accelerate time-to-market.

Plant Simulation

Empowers you to design, simulate and optimise your production processes with unparalleled precision.

The Siemens' Virtual Commissioning Advantages

Efficiency and Cost Savings

Accelerates commissioning, reduces errors and costs, and allows flexible design experimentation.

Quality and Risk Management

Ensures high-quality, reliable products through comprehensive virtual testing and early issue detection, with ongoing performance

optimisation.

Integration and Collaboration

Enables seamless system integration, enhances remote collaboration, and provides accurate simulations for predictable outcomes

Visit our Industry 4.0 Centre and see the demo in-action.

We are always happy to arrange a demo with your business to showcase a Digital Twin of a real-world machine within MCD software, whilst its physical counterpart is housed at the Siemens Industry 4.0 Centre in Manchester.

The Parmley Graham Industry 4.0 Centre is a mirror of the Siemens Digital Experience Centre based in Manchester and is filled with technology from micro automation, servo drives, redundant PLC’s, automation safety solutions and networks.

Book a tour to our Industry 4.0 Centre

Find out more about our Industry 4.0 Centre

Case Studies

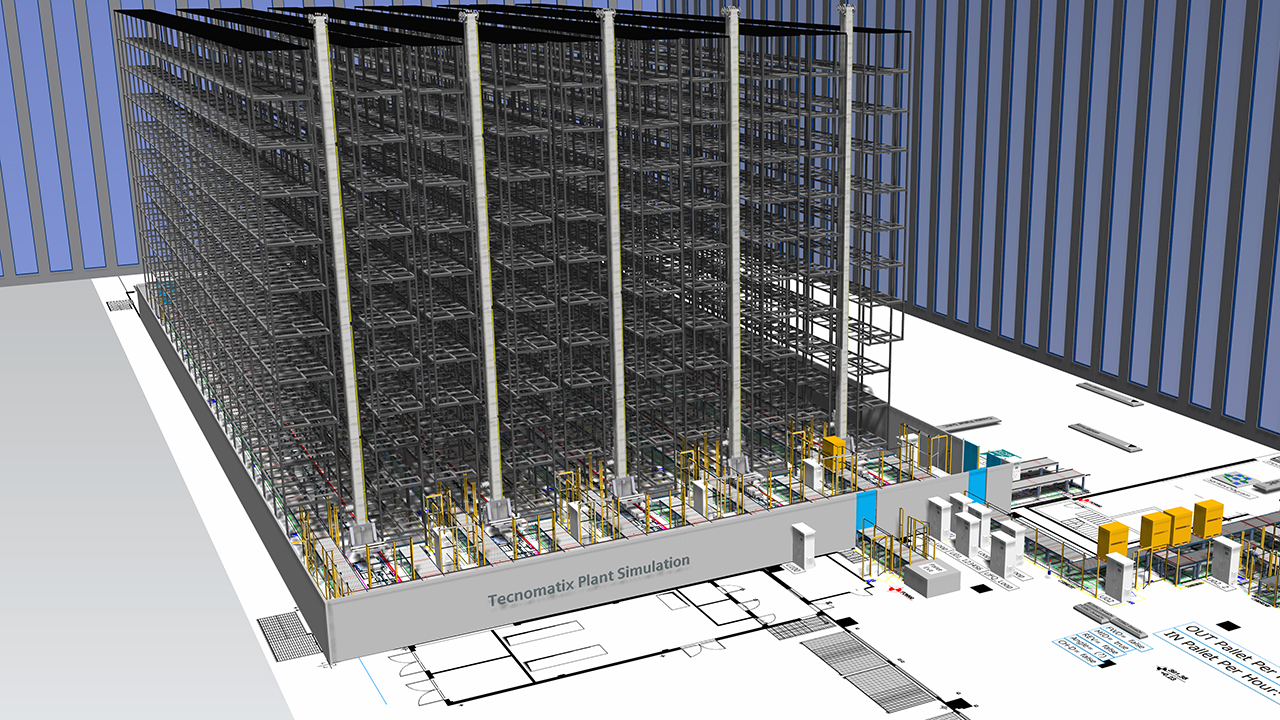

Siemens SW Ferrero (Tecnomatix)

Ferrero leverages Tecnomatix Plant Simulation to reduce the time to achieve target availability by 88 percent – using a comprehensive digital twin, reducing high-bay warehouse commissioning time by 30 percent.

Siemens SW Wipro PARI

Wipro PARI uses Process Simulate to validate engine assembly line in three months reducing commissioning time by 70 percent, improved process reliability and reduced rework by 40 to 50 percent.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.

Robotics & Automation

Overcome the complexity in developing robotics and advanced automation systems.

Harness the full potential of robotics and automation by implementing the right tools and applications. Integrate easily, reduce project cost and accelerate the development time.

Parmley Graham can help you do this. Contact our team for initial discussion, or find out more details.