Safe bar code positioning system

The FBPS 600i safety bar code positioning system from Leuze is now available with a PROFIsafe interface, making integration into safety control systems easier than ever. Users can connect the device directly to a safe PLC or choose the alternative version with two SSI interfaces. Both variants meet Performance Level e requirements, making them ideal for demanding applications such as the precise positioning of cranes and stacker cranes.

A key benefit across all models: reliable position detection using just one sensor. This reduces both integration complexity and long-term maintenance costs.

Direct PLC integration

With its PROFIsafe interface, the FBPS 600i can be seamlessly integrated into a safety control system. Alongside the safe interface, the device also features a non-safe SSI interface for direct connection to the machine drive system. The PROFIsafe model additionally supports a safe speed output function.

Configuration is straightforward via the hardware manager using a GSDML file or directly within the drive system’s configuration settings. Thanks to an integrated switch, multiple devices can also be connected in series using a linear topology if required.

Angled scanning beam for maximum reliability

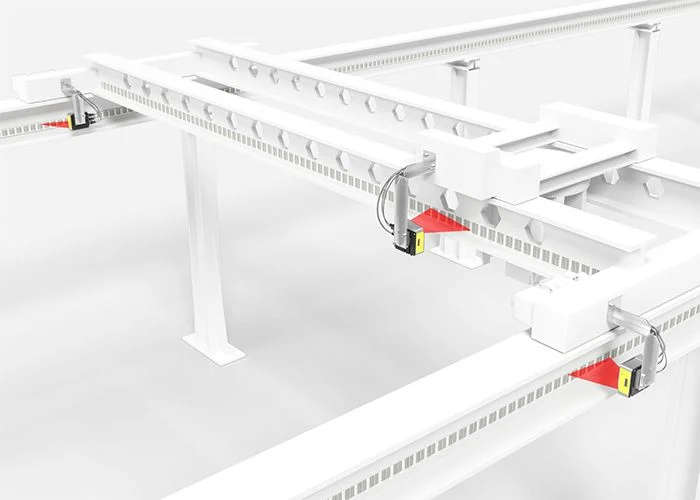

The system comprises the FBPS reading head mounted on the moving machine and the robust, UV-resistant BCB bar code tape installed in parallel. During operation, the FBPS 600i reads multiple codes per scan, enabling highly precise position values.

To further increase reliability, Leuze has designed the scanning beam at an angle, ensuring each code is captured at different points along its path. This prevents errors caused by localized dirt or damage. Combined with a fast response time of just 10 milliseconds, the system is perfectly suited for high-speed applications such as stacker cranes.

Fast and simple installation

The FBPS 600i is designed for easy mounting and quick servicing. Its wide working range (50–170 mm) and clever fastening concept mean the device can be securely attached to its clamp bracket with just one easily accessible screw. This ensures straightforward installation and rapid replacement during maintenance.

Your benefits at a glance

- Plug-and-play safety integrationCost savings with single-sensor design

- Reliable performance in tough environments

- Rapid installation & maintenance

Get in Touch

To discuss how the PG team can help, either email us at support@parmley-graham.co.uk or call 0191 478 0404.

Alternatively, click the button and complete your details: