SIMATIC WinCC Unified

The visualisation system of the future is here.

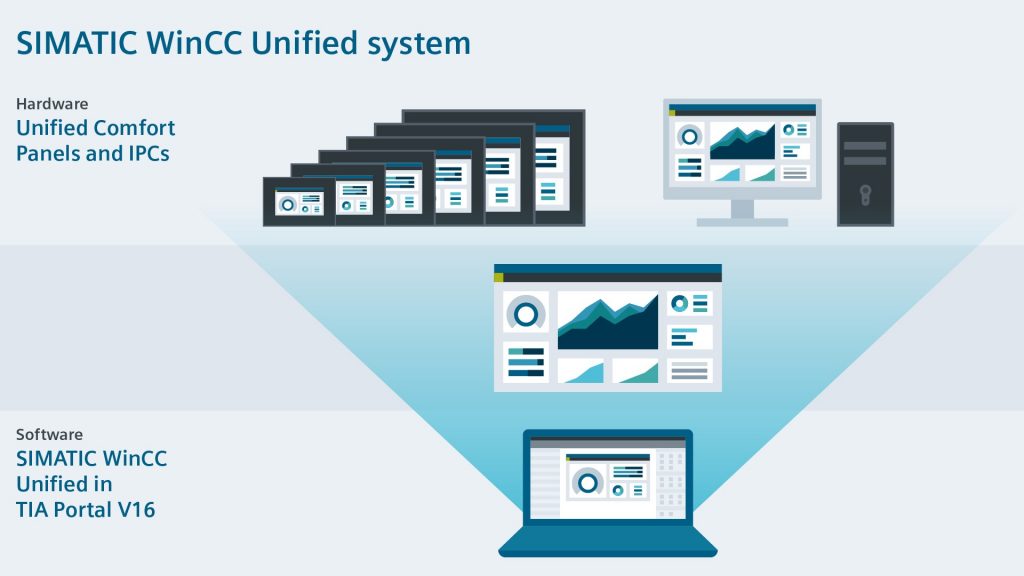

An integrated visualisation solution from Siemens combining the latest web and edge technologies with open interfaces – The SIMATIC WinCC Unified enables machine and plant builders to meet the challenges of digitalisation. SIMATIC HMI Unified Comfort Panels and PC-based systems make the most of the visualisation systems’ power allowing you to implement innovative operating concepts. Enabled with latest technology, greater scalability, accessibility anywhere and openness for a system that is ready for the challenges both now and in the future.

- High-end performance with Multitouch

- Edge-enabled

Join our FREE Workshop:

Modernisation of Visualisation: Future-proofing your visualisation platforms made easy.

Overview

Technology

- Native web technology

- Device independent

- Object-oriented approach

Scalability

- One engineering

- Panel-and-PC system

- Collaboration

Accessibility

- On-premise

- Cloud and Edge ready

- Augmented reality

Integration

- Openness

- Plant intelligence

- Integration platform

Software

SIMATIC WinCC Unified

The leading innovation of WinCC Unified software is a switchover to native web technologies such as HTML5, JavaScript and SVG. This means that users will now be able to edit SCADA programs directly on their computer, and they will naturally scale on any device (e.g. tablets and HMI screens of all sizes) without compensating functionality. Engineers should feel much more welcome to customise their programs and run them with any device, and this tried and tested platform gives you the freedom to implement your ideas as you imagine them.

Alternatively, take a look in the Industrial App Store for a range of pre-configured solutions. This platform allows you to download official applications straight to your WinCC Unified software in the same way you would download an app to your smartphone. The Industrial App Store will be an ever-evolving platform used to constantly bring new advancements and benefits to the software, and a range of downloadable solutions are already available.

Hardware

SIMATIC WinCC Unified Comfort Panels

Implementing all this to the workplace is made possible through the new SIMATIC WinCC Unified Comfort Panels, the HMI that will see long-term use in the automation world. Sporting capacitive multitouch displays, Unified Comfort Panels are integrated with Industrial Edge technology, and allow for smart navigation of the TIA Portal. Using the latest web technology, Unified Comfort Panels will be at the forefront of HMI hardware for years to come, and Siemens are leading the way with innovation.

The SIMATIC HMI Unified Comfort Panels permit innovative operating concepts based on the new SIMATIC WinCC Unified visualisation software. All devices, in sizes from 7 to 22 inches, offer the same useful interface. The new hardware also delivers considerably more power for implementing the visualisation. The system limits have been at least doubled, in some cases even tripled. This enables the implementation of significantly larger applications than before on a panel system.

Full flexibility in the choice of the runtime environment: WinCC Unified is available on all relevant platforms in industrial automation.

The new generation of high-end operator panels with Multitouch, Industrial Edge

Scalable from single-user system up to complex and distributed applications.

Talk to our experts...

Discuss your requirements and let us help you explore the right system for you

The Siemens SIMATIC WinCC Unified System Advantage

Delivering beneficial outcomes for a successful and future-proof visualisation platforms.

Improved operational efficiency

Visualisation allows operators and managers to monitor the factory’s processes, machines, and systems in real-time. By highlighting bottlenecks, underutilised resources, and areas for improvement. This immediate insight can help identify issues, inefficiencies, and potential disruptions as they occur, allowing for timely corrective actions leading to increased production efficiency and resource utilisation.

Better quality control and process optimisation

Visualisation tools can help track product quality and detect defects in real-time, ensuring that only high-quality products are dispatched to customers. By also revealing the areas of the production process that can be fine-tuned or streamlined, improved visualisation can lead to cost savings and better resource allocation.

Enhanced situational awareness

Advanced interface enables clear and intuitive representation of the factory’s status, historical data visualisation tools which allows easy analysis of trends, patterns, and historical performance significantly improving situational awareness and decision-making. This can help operators respond to changing conditions effectively for process optimisation and long-term planning.

Shorter engineering time and reduced downtime

Improved visualisation enables promptly identifying maintenance issues that can be addressed proactively, reducing unexpected downtime and costly disruptions to production while saving valuable engineering time.

Enabling sustainability strategies

Improved visualisation enables efficient monitoring of energy consumption and visualising usage patterns helping businesses achieve their sustainability goals.

Increased safety and remote accessibility

Remote access capabilities enable off-site personnel to monitor and control the factory, which can be especially useful for troubleshooting, support and ensure safety for human workforce particularly in unsuitable environment conditions.

Reduced training requirements

Standardised operating concepts, flexibility and user-friendly attributes enable shorter training time and fewer human errors.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.