Husqvarna UK

Implementing a fully automated solution to eliminate operator intervention, improve workplace ergonomics, and redeploy skilled staff to more value-adding activities.

Husqvarna Group is a global leader in innovative solutions for forest, park, and garden care, as well as equipment and diamond tools for the construction and industrial sectors. With a strong focus on sustainability, quality, and customer value, its product portfolio includes everything from robotic lawn mowers and chainsaws to watering systems and power cutters.

Business Challenge

Why the need?

Husqvarna UK Ltd identified a clear opportunity to automate their stillage packing process, a repetitive, manual task where operators inserted cardboard inserts into containers. This operation was inefficient, required significant floor space, and placed physical strain on the workforce. Their goal was to implement a fully automated solution to eliminate operator intervention, improve workplace ergonomics, and redeploy skilled staff to more value-adding activities.

This project was part of a broader Technology Foundation directive issued by Husqvarna HQ in Sweden, aimed at driving global innovation and accelerating automation initiatives across their operations. As part of this directive, the Newton Aycliffe office was tasked with advancing business development and supporting proof-of-concept technology implementations to validate and scale new automation solutions.

PG Solution

How PG helped Husqvarna

Parmley Graham began collaborating with Husqvarna in late 2023, with solution deployment occurring in spring 2024. The objective was to create a fully automated packing cell that would require minimal manual intervention.

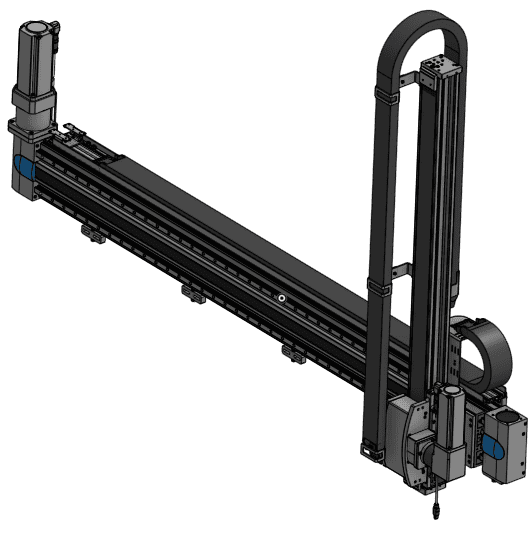

Working closely with our partner Festo, the PG team utilised the Festo Handling Guide Online (HGO) to determine payloads, speeds, and suitable mechanical components. The result was the integration of a Festo YZ Mechanical Axis system – chosen for its precision, scalability, and compatibility with Husqvarna’s operational environment.

Husqvarna opted for an electric automation solution over pneumatic alternatives. While this came with a higher initial investment, it aligned with their sustainability strategy by eliminating the need for compressed air and delivering long-term energy savings.

Our team conducted a small-scale proof of concept to ensure technical feasibility and integration with existing workflows. The Newton Aycliffe office played a key role in this stage, providing technical insight, de-risking the project, and fulfilling its role under the Technology Foundation directive to lead early-stage innovation within Husqvarna UK operations.

The final installation was carried out in-house by Husqvarna’s experienced engineering team, with Parmley Graham supporting setup, fine-tuning, and technical issue resolution.

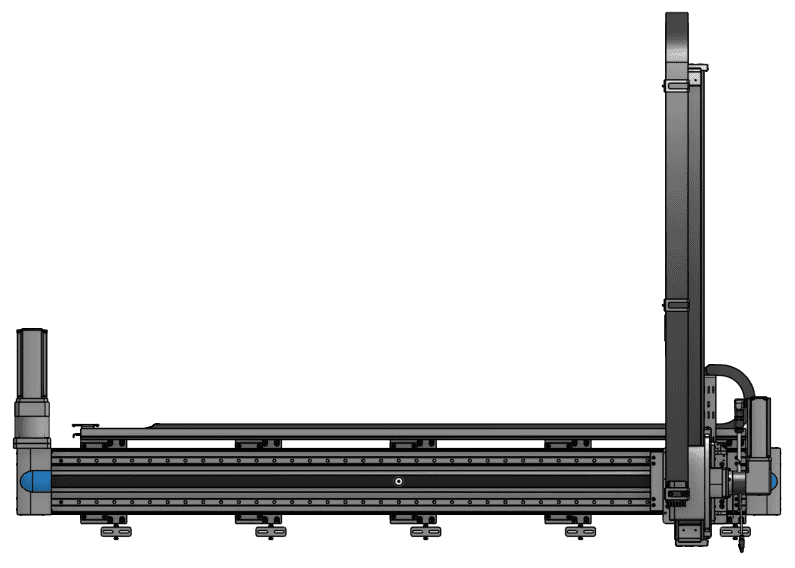

Representation of the Festo YZ Mechanical Axis System

Solution Impact

How has the new solution improved operations?

Early feedback from Husqvarna has been highly positive. The new automation cell, powered by Siemens Automation Controls and Festo YZ Mechanical Axis, has delivered immediate performance and ergonomic benefits. It is set to enhance productivity while supporting long-term sustainability goals.

Key outcomes include:

- Increased Efficiency

- Fully automated process significantly reduces cycle times.

- Improved Workplace Safety

- Eliminating repetitive manual handling.

- Energy Efficiency

- Electric automation reduces operational energy demand.

- Scalability

- Proof of concept success paves the way for wider automation adoption.

- Data & Reporting

- Integration with Siemens systems enables future expansion into data collection and performance tracking analytics.

- Future Integration

- Siemens controls enable future integration with production.

This project exemplifies how the Technology Foundation directive empowers regional teams like Newton Aycliffe to take the lead – accelerating innovation, validating emerging technologies, and driving continuous improvement across Husqvarna’s UK operations.

"This project has been a great example of how innovation, collaboration, and a clear vision can drive meaningful change. The automation solution has not only improved our operational efficiency but also aligns with our long-term goals around sustainability and workforce optimisation. We’re proud to be at the forefront of this transformation with support from our partners and the Newton Aycliffe team."

Lee Francis, Maintenance and Engineering Manager, Husqvarna UK.

"Working with Husqvarna on this project has been a fantastic opportunity to demonstrate the power of collaboration and forward-thinking engineering. By combining Festo’s YZ axis technology with Siemens automation and Husqvarna’s commitment to innovation, we were able to deliver a tailored solution that not only meets today’s operational needs but also supports their long-term automation strategy."

Niall Bennison, External Automation Engineer, Parmley Graham.

Enabling enhanced efficiency, quality and safety for Food and Beverage operations.

Discover our solutions as key enabler for efficient, excellent quality, and highly competitive operation, allowing our clients effortlessly meet the demands of a rapidly evolving market while maintaining product safety and consistency.

Get in Touch

To discuss how the PG team can help, either email us at support@parmley-graham.co.uk or call 0191 478 0404.

Alternatively, click the button and complete your details: