Production Cells or Lines - Process Simulate

To better assist you with your requirements, please speak with one of our experts. Alternatively, email our Process Instrumentation team, or call us on 01914780404.

Engineer automated production systems using robotics and automation simulation

Robotics & Automation Simulation

Engineer and optimise robotic and automated production systems using 3D robotic workcell design, simulation, and offline programming.

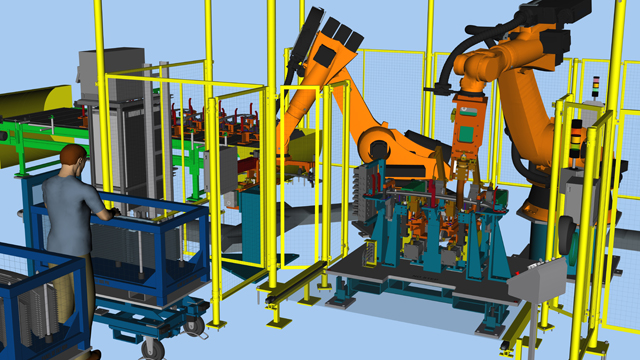

With Tecnomatix® software’s robotics and automation simulation solutions, you can work in both data-managed and file-based environments for the development of robotic and automated production systems. These tools address multiple levels of robot simulation and workstation development, from single-robot stations to complete production lines and zones. Using collaborative tools, you can enhance communication and coordination among manufacturing disciplines, enabling smarter decision-making. This allows you to bring automation systems online much faster and with fewer errors.

Mechatronic Concept Design is made up of powerful features that allow you to build a custom solution. Read more about these features below.

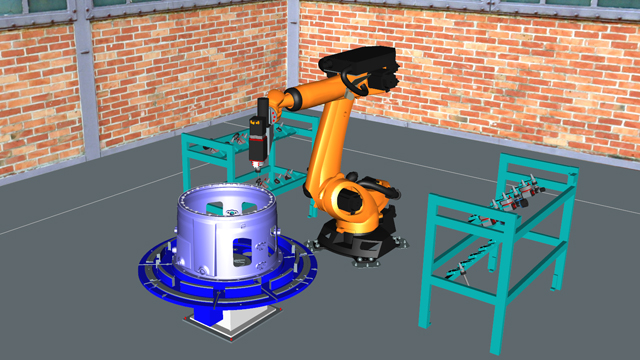

Design Complete Workcells with 3D Kinematic Models

Tecnomatix Process Simulate Robotics and RobotExpert software provide the tools necessary for the design and validation of manufacturing processes in a dynamic and highly visual environment where manufacturing engineers can author, re-use, validate and optimize manufacturing process sequences with realistic behavior using fully kinematic 3D models. These solutions support a variety of robotic and automation processes allowing for early validation of automation concepts virtually and the simulation, offline programming and commissioning of complete production systems.

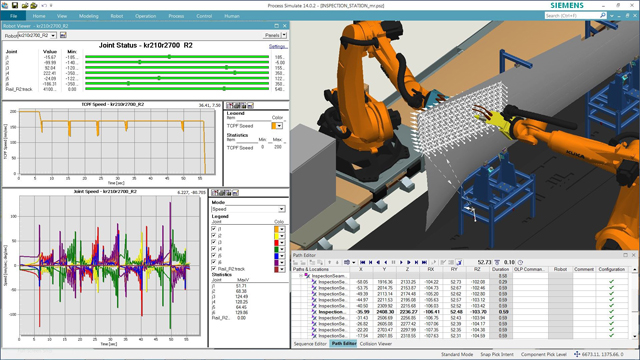

Plan, Simulate and Optimise Robotic Operation Paths

Tecnomatix robotics and automation simulation solutions give you the power to simulate complete manufacturing cells and systems allowing you to design and validate collision-free robotic paths and optimize their motion and cycle times, using both time-based and event-based simulation methods. Dedicated tools for various robotic applications, such as resistance spot welding, arc welding, cutting, spraying and pick-and-place operations further enhance your ability to define the correct motion for the robots and automation in your systems.

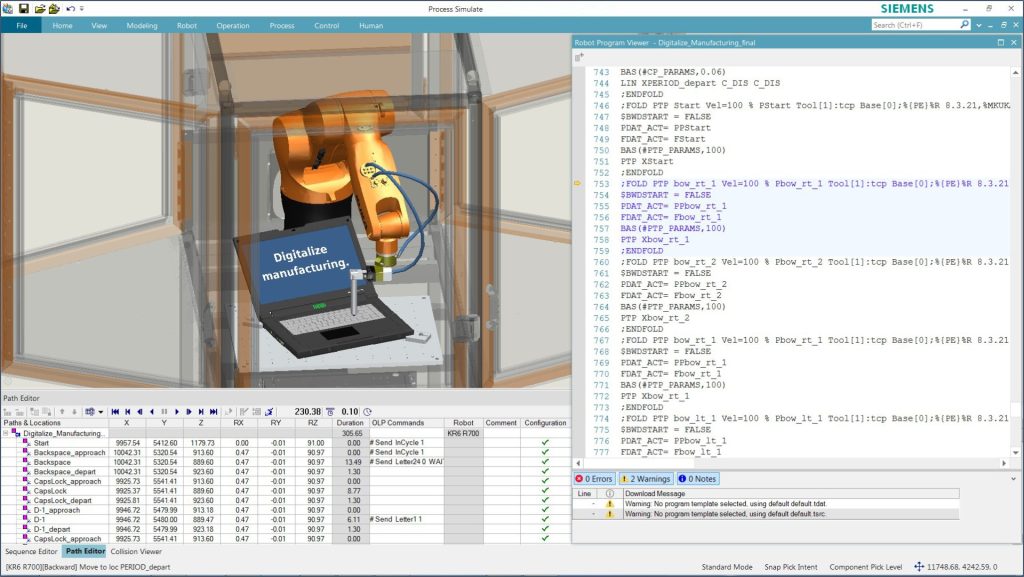

Program Robots and Automation Completely Offline

Tecnomatix software’s offline programming solution for Process Simulate and RobotExpert enables accurate simulations of robot motion sequences and the delivery of production-ready programs to and from the shop floor. Interfaces to all major industrial robots allow controller-specific motion planning, simulation and program execution. Detailed information, including motion and process attributes, can be added to the generated robot paths for the creation of complete programs downloaded to the real controller, resulting in more efficient offline programming.

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham are a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.