Motion Control

Precision and reliability for industrial operations enabling quality and cost-effective production output.

Ensuring the accurate, repeatable, and reliable movement of machinery and components in industrial processes deliver higher levels of precision, productivity, and safety in their operations.

At Parmley Graham, we bring our expertise together with high caliber products from top OEMs worldwide to develop innovative, single-source solutions for various industries.

Find out more about our solutions or browse our Motion Control products.

Overview

The move towards electric automation technology is not without its challenges. As well as extensive knowledge of electrics and software, you also need a relatively large budget – so it is no wonder that the benefits of electric automation have so far remained reserved for complex motion requirements. At Parmley Graham, we partner with top automation technology manufacturers to provide an automation solution that bridges the gap between easy-to-install pneumatics and smart electric automation, making your production more efficient: simply with plug and work.

Pneumatics continues to be the tool of choice for simple movement and positioning tasks. However, in an increasingly digitalised world, electric automation and a continuous flow of information from the workpiece to the controller and the cloud are becoming indispensable. This enables you to reduce commissioning times, ensure that production is cost-efficient and manage shorter product life cycles. The savings made during operation therefore offset the higher investment costs of electric automation solutions. Commissioning is now also quick and easy. How does it work? With our Simplified Motion Series.

Find out about the range of movements of all Simplified Motion Series components in this sample application. See how simple movements can be performed electrically – without a control cabinet, just using the drive that is integrated directly in the mechanical system.

Key components of a motion control process.

Motor Control

Motion control systems regulate and control motors, whether they are electric, hydraulic, or pneumatic, to determine the speed, position, and direction of moving parts

Positioning Systems

These systems utilise feedback from sensors to accurately position and move machinery and equipment, such as robots, conveyor belts, and CNC machines, to specific locations.

Speed and Torque Control

Motion control systems enable the adjustment of motor speed and torque to meet the specific requirements of different manufacturing tasks.

Path Planning

In robotics, motion control involves planning the path that the robot’s end-effector (e.g., an arm or tool) follows to ensure it reaches its target efficiently and accurately.

Feedback Systems

Motion control often relies on sensors like encoders and resolvers to provide real-time feedback on the position and speed of moving parts. This information is essential for closed-loop control to maintain accuracy.

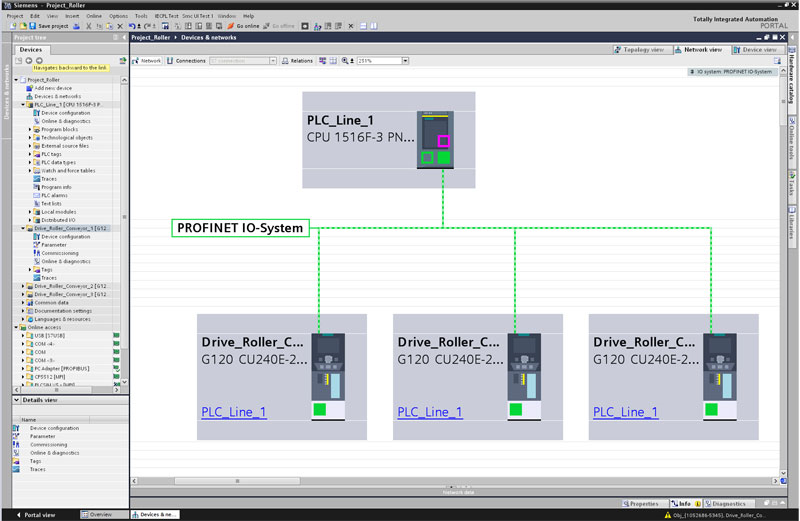

Programmable Logic Controllers (PLCs) and Software

Industrial controllers and software programs are used to create and execute motion control sequences, often involving complex logic and coordination of multiple devices.

Safety Systems

Motion control systems include safety features to protect workers and prevent accidents, such as emergency stop buttons and collision detection.

Automation

Automation is a primary application of motion control, where tasks that involve repetitive or precise movements are handled by machines or robots instead of human operators.

Applications

Motion control is used in a wide range of industrial applications, from simple tasks like opening and closing valves to complex tasks like precision cutting, welding, and assembly in automotive manufacturing.

Key Benefits

Delivering value through improved quality, efficiency, and reduced operational cost.

Precision and Accuracy

Motion control systems provide precise and accurate control over the movement of machinery and equipment, ensuring that tasks are performed with minimal error.

Consistent Output Quality

By reducing variations and errors, motion control systems help maintain consistent product quality, which is crucial for meeting quality standards and customer expectations.

Increased Productivity

Automation through motion control reduces the reliance on manual labor in repetitive tasks, leading to higher productivity, faster production cycles, and extended operating hours.

Reduced Downtime

Motion control systems monitor equipment and machinery, allowing for predictive maintenance to prevent breakdowns and minimize unplanned downtime, resulting in increased equipment uptime.

Versatility

Motion control systems can be adapted to a wide range of manufacturing tasks and product variations, making them versatile and suitable for various applications.

Energy Efficiency

The precise control of machinery and equipment optimizes energy consumption, leading to reduced operating costs and a smaller environmental footprint.

Enhanced Safety

Implementing safety features within motion control systems ensures that equipment operates safely, protecting both workers and the equipment itself.

Improved Ergonomics

Reducing the need for manual labor in physically demanding tasks improves workplace ergonomics, reducing the risk of worker injuries.

Reduced Cost

While there is an initial investment, motion control systems can lead to long-term cost savings by reducing labor costs, material waste, and maintenance expenses.

Continuous Operation

Motion control systems can operate 24/7 without fatigue, ensuring continuous production.

Data Collection & Analysis

Many motion control systems offer data collection capabilities, which can be analysed to identify performance trends and areas for optimisation.

Reduced Waste

Precise motion control minimises waste by ensuring that raw materials and resources are used efficiently.

Increased Competitiveness

By improving quality, productivity, and efficiency, motion control helps factories remain competitive in a global market.

Quick Changeovers

Motion control systems can be reprogrammed and reconfigured easily, allowing for fast changeovers between different production runs.

Scalability

Motion control systems can be scaled to accommodate the growing needs of the factory.

Efficient Motion Control

Implement innovative motion control solutions simply, quickly, safely.

Build innovative machines faster and without costly prototyping, so you can more easily meet your customers' needs.

Industry applications

Food and Beverage

Motion control is employed to automate food and beverage production processes such as conveyor systems for transporting ingredients, robotic arms for packaging, and automated machinery for food processing, enhancing accuracy, speed, and consistency in production, contributing to improved quality and efficiency.

Logistics

Motion control in logistics involves the use of automated systems to manage and optimise the movement of goods, enhancing efficiency and reducing manual labour. Precise and synchronised handling, improves overall operational performance.

Products used in Motion Control

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham are a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.