Why should you adopt virtual commissioning today?

This year we have been discussing the many benefits of using Siemens PLM Software with UK OEM’s / Machine Builders. Through a number of hands on customer workshops we have been demonstrating how you can reduce total time required for commissioning a machine by as much as 70%.

Talk to us to discuss your questions and requirements.

Find out more about our virtual commissioning products.

Watch the videos below to learn more about this cutting edge technology.

Phase 1

Phase 2

Phase 3

Phase 4

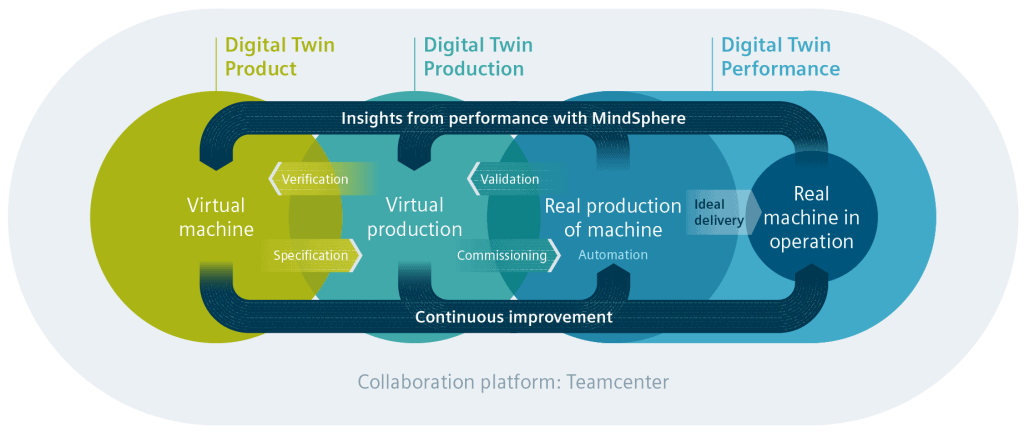

The digital twin in machine building.

Siemens comprehensive concept of the digital twin consists of three forms: the digital twin of the product, the digital twin of production, and the digital twin of the performance of both product and production. Thanks to our comprehensive domain expertise and optimized tools, Siemens is the only company that offers this holistic approach and is able to create the closed-loop connection between the virtual world of product development and production planning with the physical world of production system and product performance. Through this connection actionable insight is gained from the physical world for informed decisions throughout the lifecycle of products and production operations.

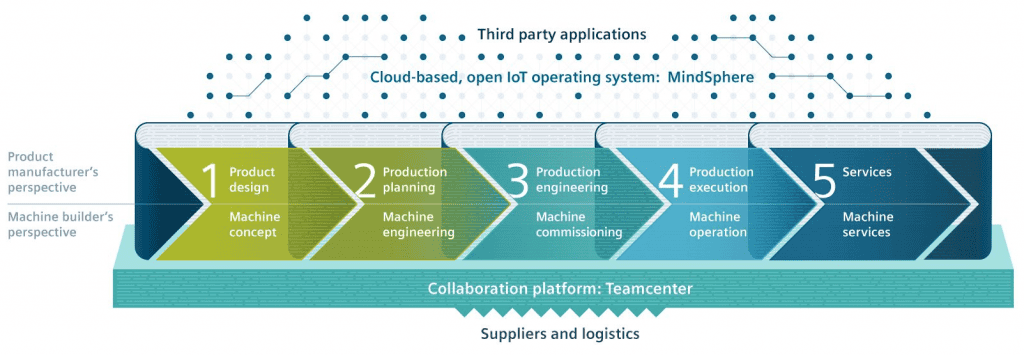

Holistic approach

The Digital Enterprise Suite enables manufacturing companies to integrate and digitalise their business processes – including their suppliers. They can start at any point in their value chain, from product design to production planning, production engineering, production execution, and services, and expand the digitalisation process step by step. The same goes for machine building: from the machine design to engineering, commissioning, machine operation, and services.

Case Studies

Tronrud Engineering Case Study

Trakrap Case Study

Rosendahl Nextrom Case Study

Talk to us to discuss your questions and requirements.

Find out more about our virtual commissioning products.